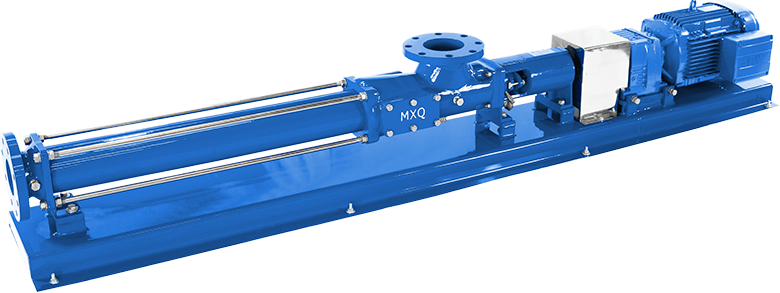

MXQ progressive cavity pumps are 100% Bornemann® equivalent (fit, form, and function).

MXQ progressive cavity pumps are self-priming, positive displacement pumps. They consist of two elements: the rotating helical rotor and the stationary stator. The rotor conveys the medium with low pulsation and vibration through the stator. The flow rate is proportional to the speed of rotation, so increasing the speed will increase the flow. Additionally, increasing the number of stages (rotor pitches) raises the pump pressure proportionally. The MXQ design allows pumping in both directions, a high suction lift, and low shear conveying. MXQ progressive cavity pumps are suitable for all sectors of industry for pumping and dosing thin to highly viscous, neutral, or aggressive media, with or without solid or fiber content. The pump materials of construction will be based upon the application. This wide range of media processing and various standard models offered means MXQ progressive cavity pumps can move almost anything.

1. EH Universal Pumps : The Bornemann® equivalent EH universal pumps are horizontal pumps, which are most commonly used for low or high viscous media. Almost any type of driver can be used to drive these pumps. They feature a capacity up to 1,400 GPM, are can handle operating temperatures up to 360 °F, and have a differential pressure up to 360 PSI.

2. EL Close Coupled Pumps: The EL close coupled pumps are shorter in length, as compared to the EH pumps. The close coupled design no only eliminates the need for a base plate, but is also much more space efficient. These pumps are suitable for use with neutral or aggressive media, with thin or high viscosity. The EL models come in 1 stage (90 PSI) and 2-stage (180 PSI) variants. They have a capacity up to 350 GPM, and differential pressures up to 180 PSI.

3. ER Open Hopper Pumps: If you have a requirement of handling heavy, or extremely viscous fluids, then the ER open hopper pumps are an ideal match. As their name suggests, these pumps feature an open hopper and auger feeder. The ER models have a capacity up to 880 GPM, and differential pressures up to 360 PSI. They are capable of pumping up to 60% solids!

In 2015, Bornemann Pumps Inc.® stopped manufacturing their progressive cavity pump product line and MXQ acquired the complete USA stock of pumps and spare parts. After some reverse engineering and development, MXQ was able to develop their own progressive cavity product line that is 100% Bornemann equivalent.

MXQ Progressive Cavity Pumps are self-priming, rotating, and valve-free positive displacement pumps that can process everything from thin liquids to viscous media. They reliably process even media with non-Newtonian viscosity characteristics, as well as abrasive, neutral, and aggressive media.

MXQ Progressive Cavity pumps are used in the following industries:

*Bornemann® is a registered trademark of ITT Bornemann GmbH. MXQ is not an authorized distributor of parts or services for ITT Bornemann GmbH. MXQ is not associated with, endorsed by, or sponsored by ITT Bornemann GmbH.

| PART | MATERIALS |

|---|---|

| Pump Casing* | GG-25 - Cast Iron 1.4408 - 316 SS 1.4571 - 316 SS 1.4581 - CF8M SS 1.4462 - Duplex SS |

| Rotor* | C45 Hard Chrome - HCPTS 1.4571 - 316 SS 1.4462 - Duplex SS |

| Shaft* | 1.4021 - Carbon Steel 1.4571 - 316 SS 1.4462 - Duplex SS |

| Stator* | SBR (Buna) NBR (Perbunan) HNBR (Therban) FKM (*Viton) IIR (Butyl Rubber) CSM (Hypalon) EPDM (EPDM) *Viton is a registered trademark of the DuPont company. |