A progressive cavity pump is referred by different names, such as eccentric screw pump, progg cavity pump, or cavity pump. These are positive displacement pumps, which are most commonly used in fluid handling systems. The special design of these pumps allows the user to use it efficiently in a number of industrial applications. Are you intrigued to know more about the designing of these pumps? Then, the following post will help you to understand it. The post covers in detail the progressive cavity pump design, along with its working principle. Also discussed in the post are several benefits of these pumps, which make them popular in a variety of applications.

What is the Working Principle of Progressive Cavity Pumps?

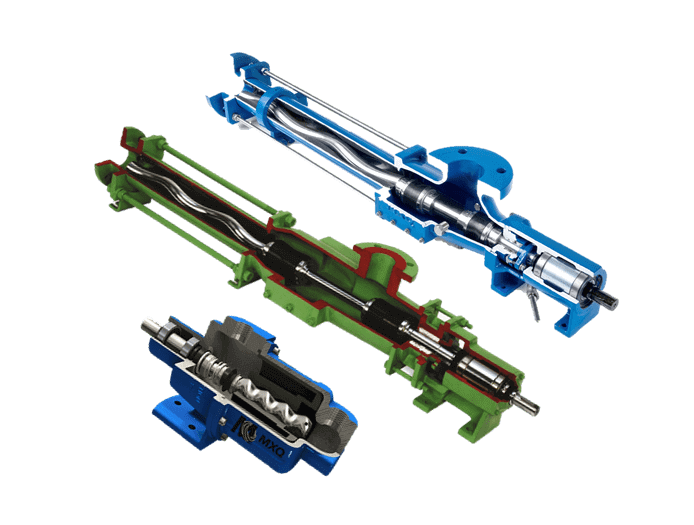

The rotor and the stator are the two crucial components of the progressive cavity pumps. As the rotor rotates, it forms a tight seal with the stator. Furthermore, it forms a set of cavities having a fixed size in between. Now, when the rotor is rotated using a motor, the cavities also move. However, the volume, shape, and size of the cavities remain the same. The required material, which is pumped in moves inside the pump cavity.

What are the Reasons Behind the Increasing Popularity of Progressive Cavity Pumps?

These pumps are known to have a number of benefits, which act as the reasons behind their increasing popularity. The benefits of the progressive cavity pumps are as follows:

- Capable of Handling High Pressures: Often, the pumps used in fluid handling systems are required to handle high pressures. The progressive cavity pumps have the capability to handle pressures up to 80 bar, which is one of the reasons that makes them popular.

- Prevents Backflow: Unlike regular pumps, these eccentric screw pumps prevent the backflow when stopped. These pumps close like a slider to stop the backflow from returning to the pump.

- Exceptional Metering Precision: These pumps are known to have low pulsation. Thus, it helps them deliver an exceptional metering accuracy, thus eliminating the need for an additional valve.

- Efficient Handling of Diverse Viscosities: The progg cavity pumps have the capability to handle media of diverse viscosities. They can handle media with low to high viscosities, as well as entrained or thixotropic air fluids efficiently. This makes them highly preferable in most applications.

- Delivers Outstanding Suction Performance: This is yet another advantage of using these pumps. They are known to deliver excellent suction performance, which is why most industries and applications demand the use of these pumps.

Where are the Progressive Cavity Pumps Useful?

There are not one, but many applications of these pumps. Some most common among them include:

- Food and Beverages Industry

- Pharmaceutical Industry

- Chemistry

- Biochemistry

- Paints and Coatings

All the benefits given above clearly explain why these pumps are being used increasingly in a variety of industrial applications. Truly, they are the most efficient solution, when it comes to fluid handling. They can be availed from a variety of manufacturers in the US. However, sourcing them from those manufacturers, or suppliers, who have a good experience in the field is always advisable. This is because, it will help you ensure that you get only the best quality. MXQ USA is one such experienced manufacturer in the US, with whom you can find a variety of progressive cavity pump designs to select from, depending on your application requirements.