In most industries, fluid handling is one of the most important concerns. To carry out this process a company must have the correct equipment. There are a number of options depending on the application, but reliability, quality and performance will always be required for an efficient process. One option, which is widely used for industrial fluid handling applications, is the progressive cavity pump. These pumps are also referred to as “PC” pumps. There are a number of progressive cavity pump manufacturers in the USA, but MXQ differentiates itself by not only delivering high quality, reliable products, but also catering to its clients on a more personal level.

What are Progressive Cavity Pumps?

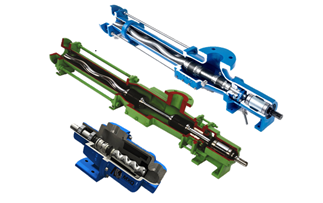

Progressive cavity pumps are self-priming, positive displacement pumps. They consist of two elements: the rotating eccentric screw and the stationary stator. The rotor conveys the medium with low pulsation and vibration through the stator. The flow rate is proportional to the speed of rotation, so increasing the speed will increase the flow. Additionally, increasing the number of stages (rotor pitches) raises the pump pressure proportionally. The design allows pumping in both directions, a high suction lift, and low shear conveying.

How do Progressive Cavity Pumps Work?

The working of these pumps is very easy to understand.

- As the rotor rotates, it forms a tight seal against the flexible rubber. This forms cavities, which are sealed tightly.

- These cavities then carry the liquid or fluid towards the discharge port.

- Since the cavities between stator and rotor are tightly sealed, the pumped liquid does not change its size or shape (low shear).

- The overall design of these pumps, helps the fluid to move at a very steady rate.

- Liquid plays the role of a lubricant between the pumping elements.

What Models of Progressive Cavity Pumps does MXQ offer?

The following three brands of the progressive cavity pumps:

1. Bornemann® Equivalent EH Pumps (MXQ):

The Bornemann® equivalent EH pumps are among the most popular types of pumps, owing to their excellent reliability, versatility, and performance. MXQ also offers Bornemann® equivalent EL and ER models.

2. Netzsch® Equivalent Pumps: These pumps are economical, and provide a cost-effective solution in a variety of applications.

3. Moyno® Equivalent Pumps: The Moyno® equivalent pumps are ideal for use in applications, such as limestone slurries, wastewater treatment, polymers, etc. MXQ provides equivalent pumps to the Moyno® 34401 wobble rotor pump and 2000 series pumps.